Our product

Concretene is a graphene-based liquid admixture that improves the microstructure of concrete, lowering embodied carbon through reduction in cement for equivalent or improved performance. The product will be cost-neutral at scale, building code-compliant and added at the batching plant like any other admixture, requiring no new equipment or training.

We have worked with major concrete suppliers Breedon, Cemex and Roger Bullivant to optimise our formulation for their low-carbon mix designs, delivering compressive strength uplifts (10-20%) in both ready-mix and pre-cast concrete applications. We are also working with global design and engineering consultancy Arup on the accreditation and assurance pathway for commercialisation of our product.

Standards and supply chain

We have addressed the challenge of a lack of standards in the emerging graphene industry – via an Innovate UK-funded project – working with manufacturers to establish quality assurance and specifications for use of graphene nanoplatelets in concrete and cement.

In contrast to graphene manufacturers who are seeking a market for their own material, we are graphene agnostic and partnering with those who marry the best-performing raw material with sustainable production, for example using nanoplatelets deriving from waste streams from the energy and wastewater sectors.

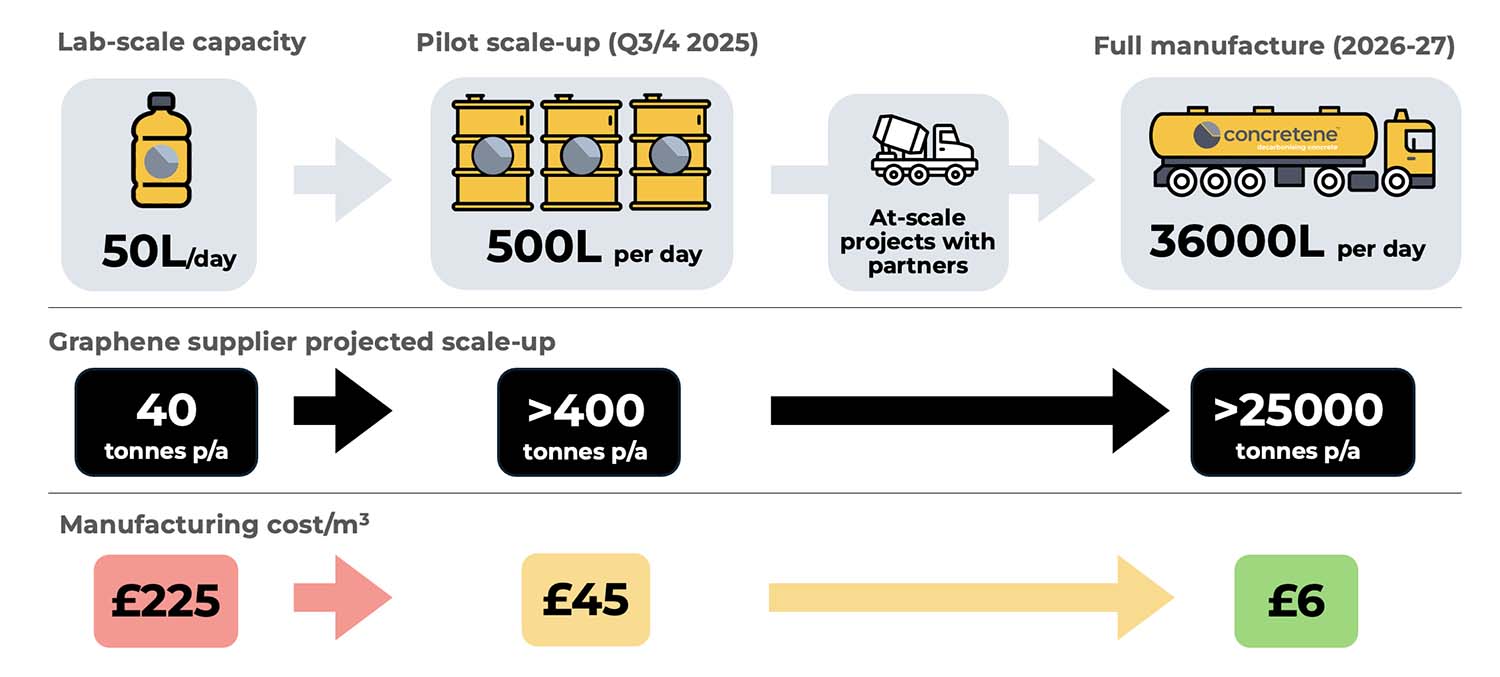

We will have a pilot plant on stream in Q3/4 2025 to service a pipeline of at-scale demonstrator projects for data assurance and we are aiming for full manufacture and commercial roll-out in 2026-27. With economies of scale from our supply chain, we anticipate a cost-to-manufacture of ~£6/m3 of concrete at full production.